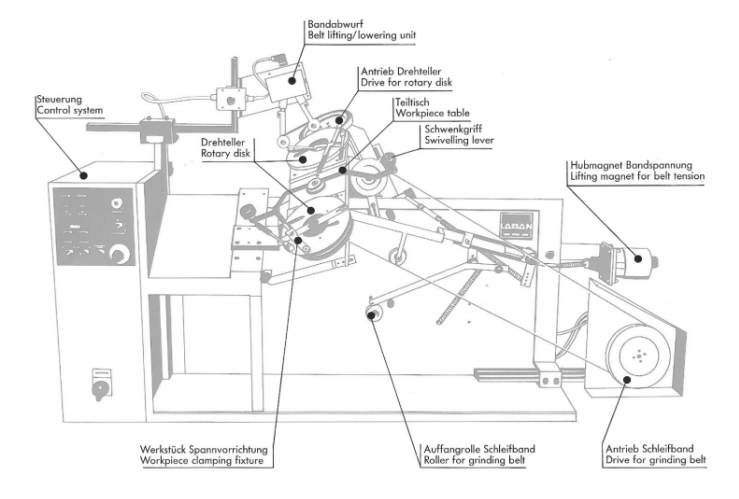

IRM 3

The inner ring grinding and polishing machine IRM 3 is particularly well suitable for grinding and polishing of all kinds of scissors,

claps and annular instruments as well as oval grip rings,

e.g. plaster scissors.

Most remarkable advantages

- Economic production

- Mechanical introduction

- Automatic belt lifting/lowering by means of a lifting magnet

- Simultaneous grinding and placement

- Speed of the rotating drive plate infinitely variable

- Pressure of grinding belt can be adjusted

- Higher surface quality

- Short machining time of 3-4 sec. per workpiece

- Properly finished material

Technical Data

Operating Voltage:

- Standard 380 V, 50 cycles

- Other voltages possible, upon request

- Fuse protection 3 x 16 A

- Control voltage 220 V

- Constant voltage 200 V

Drive Motor for Grinding Belt

- Power 1400 – 2800 rpm / 1,1 – 1,4 kW

- Drive Motor for Rotary Disk

- Gear DC motor 3000rpm, 120 W

Dimensions

- Weight approx. 250 kg

- Length / Width / Height = 2150 mm / 900 mm / 1300 mm

The inner ring grinding and polishing machine is particularly well suitable for grinding and polishing of all kinds of scissors,

claps and annular instruments as well as oval grip rings,

e.g. plaster scissors.

Most remarkable advantages

- Economic production

- Mechanical introduction

- Automatic belt lifting/lowering by means of a lifting magnet

- Simultaneous grinding and placement

- Speed of the rotating drive plate infinitely variable

- Pressure of grinding belt can be adjusted

- Higher surface quality

- Short machining time of 3-4 sec. per workpiece

- Properly finished material

Technical Data

Operating Voltage:

- Standard 380 V, 50 cycles

- Other voltages possible, upon request

- Fuse protection 3 x 16 A

- Control voltage 220 V

- Constant voltage 200 V

Drive Motor for Grinding Belt

- Power 1400 – 2800 rpm / 1,1 – 1,4 kW

- Drive Motor for Rotary Disk

- Gear DC motor 3000rpm, 120 W

Dimensions

- Weight approx. 250 kg

- Length / Width / Height = 2150 mm / 900 mm / 1300 mm