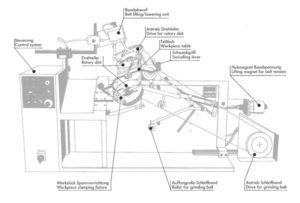

IRM 3 – Inner Ring Grinding and Polishing Machine

The inner ring grinding and polishing machine is particularly developed for grinding and polishing scissors, clamps and surgical ring instruments. It is well suitable for grinding and polishing oval handrims, claps and annular instruments as well as oval grip rings, e.g. plaster scissors and similar tools.

Technical Data

Operating Voltage:

- Standard 380 V, 50 cycles

- Other voltages possible, upon request

- Fuse protection 3 x 16 A

- Control voltage 220 V

- Constant voltage 200 V

Drive Motor for Grinding Belt

- Power 1400 – 2800 rpm / 1,1 – 1,4 kW

Drive Motor for Rotary Disk

- Gear DC motor 3000rpm, 120 W

Dimensions

- Weight approx. 250 kg

- Length / Width / Height = 2150 mm / 900 mm / 1300 mm

IRM 3 – PRICE

We’d like to submit an attractive offer to you.

Price IRM 3: Price on application

Delivery time: Min. 6 months